Is a rack and pinion assembly leak a serious problem?

In modern vehicles, the steering system has evolved from traditional mechanical steering to hydraulic or electric power steering systems. As a key component of hydraulic power steering systems, the rack and pinion assembly (R&P) is widely used in various sedans, SUVs, and light commercial vehicles.

This assembly converts steering wheel rotation into tire movement through the meshing of the steering rack and pinion, thereby achieving vehicle steering.

However, the R&P assembly also has its own complex hydraulic operating principles. Hydraulic fluid leaks can often lead to system failure, reduced driving performance, and even potential safety hazards. Serious R&P assembly fluid leakage is a common problem in daily vehicle use and must be promptly addressed.

This article addresses the question, "Is a rack and pinion assembly leak a serious problem?" and discusses in detail the structure of the R&P assembly, the causes, potential consequences, and solutions for hydraulic fluid leaks.

The Structure and Principle of the Rack and Pinion Assembly

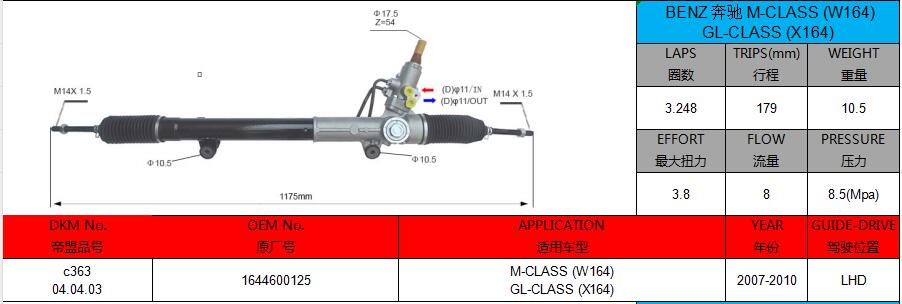

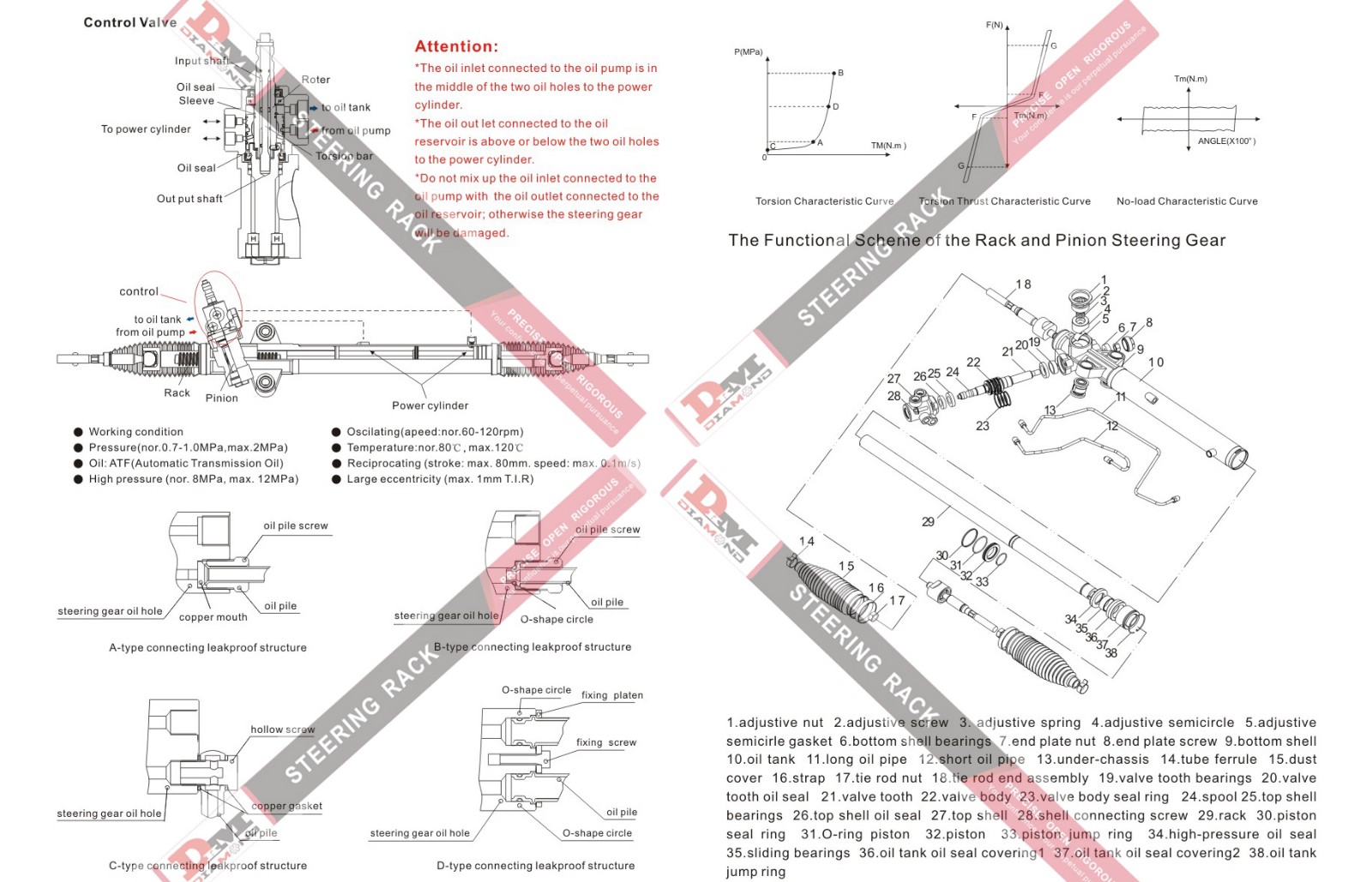

The rack and pinion assembly is a crucial component in hydraulic power steering systems. Its basic structure includes the following:

·Rack: A long, toothed rack fixed to the vehicle's steering frame. Its primary function is to convert the rotational motion of the steering pinion into linear motion, pushing the steering rod or steering arm to steer the wheels.

·Pinion: The pinion meshes with the rack and is typically connected to the steering shaft of the steering wheel. The pinion's rotation converts steering wheel rotation into linear displacement of the rack.

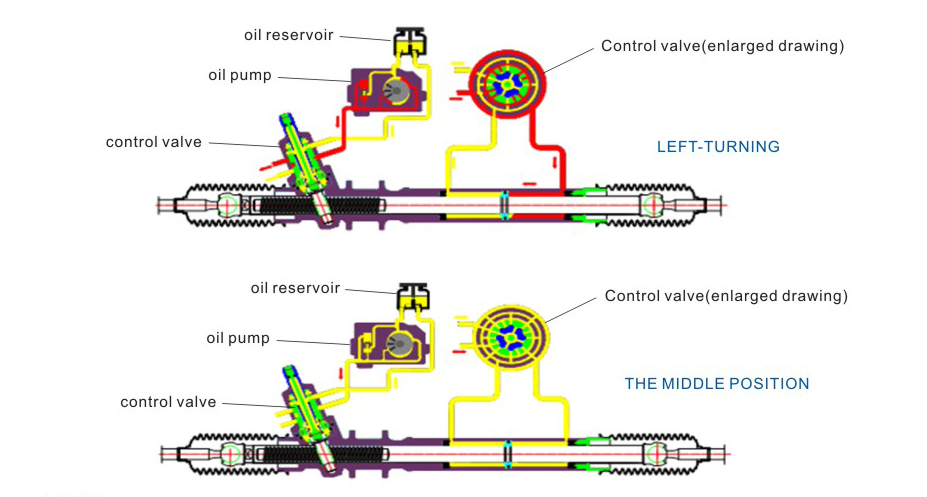

·Hydraulic Power Steering System: In modern hydraulic power steering systems, hydraulic oil is the power source for steering. A hydraulic pump delivers hydraulic oil through pipes to the rack and pinion gear assembly. The oil's pressure pushes the rack, helping the driver to easily turn the steering wheel.

In this system, the hydraulic oil, through the pump, pipes, and multiple sealing components, ensures that the oil flows throughout the rack and pinion assembly and maintains normal system pressure. However, due to long-term use, environmental factors, friction loss, and other issues, hydraulic fluid may leak outside the system, causing adverse consequences.

What are the causes of rack and pinion assembly leakage?

Hydraulic fluid leakage is often related to damage or aging of the seals in the hydraulic system. Specifically, the main causes of rack and pinion gear assembly leakage include the following:

1. Aging or Damaged Seals

Seals in the hydraulic system of the rack and pinion gear assembly play a vital role. As hydraulic fluid flows through the system, seals must prevent leakage from the joints. However, over time, seal material may lose its elasticity due to aging, hardening, or wear, leading to hydraulic fluid leakage. Especially in the high-pressure section of the steering system, seal damage can cause large-scale leakage, resulting in serious failure.

2. Cracked or Loose Hydraulic Oil Pipes

The hydraulic system's oil pipes are responsible for transporting hydraulic fluid to the rack and pinion gear assembly. If cracks or ruptures occur in the pipes due to aging, wear, or collision, hydraulic fluid can leak through the damaged areas. Additionally, loose joints and poor seals at the oil line connections can also cause fluid leaks.

3. Rack and Pinion Wear

Wear between the rack and pinion, especially if lubrication is inadequate or the hydraulic fluid is substandard, can increase friction and lead to cracks or damage in the contact surfaces. When defects develop in the meshing area of the rack and pinion, hydraulic fluid may leak through these defects.

4. High Temperature or External Environmental Factors

Prolonged use in high temperatures or extreme environments can cause deformation, aging, or damage to the seals in the rack and pinion assembly. Thermal expansion can cause excessive hydraulic fluid pressure in the system, further increasing the potential for leakage.

5. Excessive Hydraulic System Pressure

If the vehicle's hydraulic system is faulty or the pressure is improperly regulated, excessive hydraulic pressure can put extreme pressure on seals and oil lines, causing hydraulic fluid leaks. Under high pressure, the sealing performance of the rack and pinion assembly is severely degraded, leading to hydraulic fluid leaks.

What are the consequences of a rack and pinion assembly leak?

When the rack and pinion gear assembly leaks, a series of consequences can occur, affecting not only steering performance but also potentially posing safety risks. The specific consequences are as follows:

1. Loss of Steering Assist

Hydraulic fluid leakage can lead to insufficient fluid pressure in the hydraulic system, reducing or completely eliminating the hydraulic assist function. This means the driver will feel the steering wheel becomes heavy and difficult to operate, especially at low speeds.

2. Steering System Damage

Hydraulic fluid is essential for the lubrication of the steering system. If a severe hydraulic fluid leak results in a low oil level, the rack and pinion will not receive adequate lubrication. Prolonged lack of lubrication accelerates component wear and may even damage the rack and pinion, rendering the entire steering system inoperable.

3. Potential Safety Risks

Hydraulic fluid leakage can not only affect steering performance but also cause fluid to leak into the engine compartment, creating a fire hazard. Furthermore, steering system failure can affect the driver's control of the vehicle, increasing the risk of an accident.

4. Increased Repair Costs

If hydraulic system leaks are not repaired promptly, they can lead to more serious damage, further increasing repair costs. Repairing a leak may require replacing seals, oil lines, or even the entire rack and pinion assembly. If left unrepaired for an extended period, other critical components in the steering system may need to be replaced, significantly increasing repair costs.

5. Environmental Pollution

Hydraulic fluid leaks not only damage the steering system but also pose a risk to the environment. Hydraulic fluid is a type of industrial lubricant and is somewhat toxic. If a leak is not promptly addressed, it can contaminate the ground, water, and air. Therefore, promptly repairing a leak not only helps maintain vehicle performance but also reduces the risk of environmental pollution.

How to Fix a Rack and Pinion Assembly Leak?

If a rack and pinion assembly leak is discovered, the owner should take prompt action to resolve the issue. The following are some tips for addressing leaks:

1. Check the Hydraulic Fluid Level

A common consequence of a leak is a decrease in the hydraulic fluid level, so the first step is to check the hydraulic fluid level. This can be done through the window in the hydraulic tank or the dipstick. If the level is below the minimum, refill with the appropriate amount of hydraulic fluid.

2. Check the Leak Location

The owner can identify the leak's location by inspecting the hydraulic system's oil pipes, seals, and the connection between the rack and pinion assembly. If a seal is deteriorating or a pipe is cracked, it should be replaced promptly.

3. Replace Damaged Parts

If seals, oil pipes, racks, or pinions are severely worn or damaged, they must be replaced promptly. Ignoring these issues can lead to more serious damage and affect the proper functioning of the steering system.

4. Regular Maintenance and Inspection

Regularly checking the hydraulic oil quality and level, cleaning any sediment in the hydraulic system, and ensuring that no air enters the system will help maintain proper system operation. Car owners should perform regular maintenance and repairs according to their vehicle's manual to prevent leaks.

5. Professional Repair

If the owner is unable to repair the leak themselves, they should seek professional repair assistance immediately. Professional technicians can use pressure testing and hydraulic system analysis to pinpoint the leak and repair or replace the relevant components.

What purchasing options do you offer?

DKM supports flexible purchasing models ranging from single-unit orders to high-volume wholesale buys. As a manufacturer with USD5–10million annual sales, we accommodate both small and large OEMs, distributors, and online retailers. You can request quotes, explore discounted promotions, or establish a customized supply agreement.

We also offer low-price options and bulk pricing for dealers and wholesalers ordering steering racks or steering wheel assemblies in large quantities.