When did power steering rack become common?

As an important component of modern cars, power steering system has become an important technology to improve driving comfort and controllability. From the initial manual steering system to today's electric and hydraulic power steering systems, the automotive industry has undergone many changes in steering technology. In particular, the popularity of power steering rack has not only changed the way cars steer, but also improved the safety and convenience of the driving experience.

So, how did power steering rack gradually become popular from a relatively niche technology? This article will delve into the historical background, technological evolution and market demand of the popularity of power steering rack, and analyze the reasons behind this technological change.

The origin and early development of power steering system

Before the popularity of power steering rack, traditional car steering systems were usually manual steering systems. In the early 20th century, manual steering systems were almost standard in car design. This system consists of mechanical components, and the driver needs to turn the steering wheel hard to control the car, especially at low speed or when stopped, the driver needs to apply greater force. For the car design at that time, although this steering method was simple in structure, it was less comfortable to operate, especially for heavy vehicles or large cars, steering became more laborious.

With the development of the automobile industry, especially in the mid-20th century, cars gradually tended to be more diversified, heavier and faster. The manual steering system gradually exposed its shortcomings, especially in terms of driver controllability, comfort, and fatigue after long-term driving. Therefore, the power steering system came into being and became one of the key technologies to improve the traditional steering method.

The evolution of power steering technology and the rise of rack system

1. Manual steering to hydraulic power steering

In the 1930s, with the development of the automobile industry, driving comfort and safety became the design focus of major automobile manufacturers. The earliest power steering technology was first introduced by General Motors (GM) in the United States in the 1930s. Hydraulic Power Steering (HPS) technology transfers part of the power to the steering system through a hydraulic pump, thereby reducing the force that the driver needs to apply.

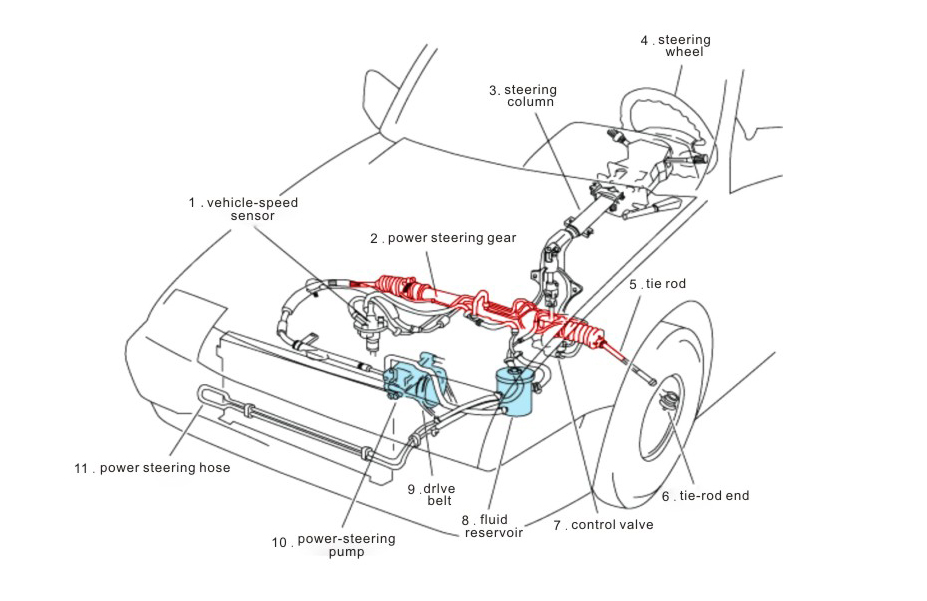

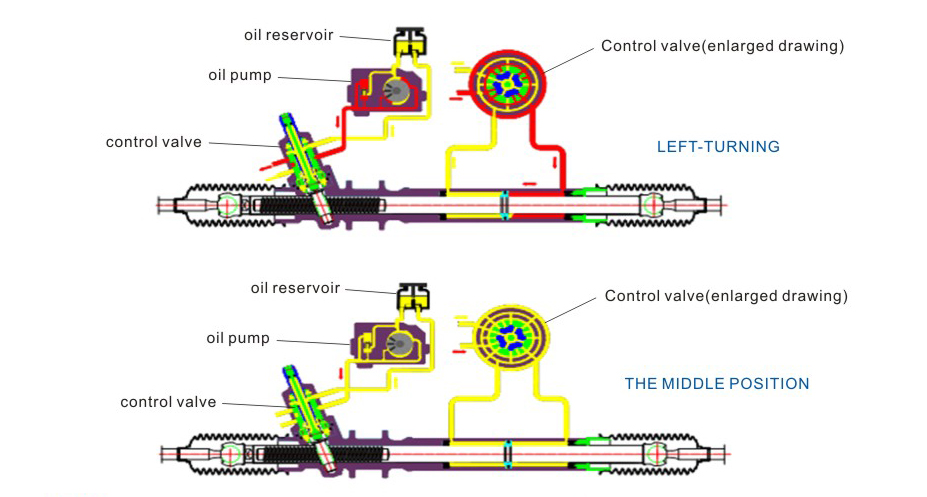

In the hydraulic power steering system, the hydraulic pump provides power through the steering rack or steering column, and the driver can control the vehicle by simply turning the steering wheel. This hydraulic power steering technology greatly improves driving comfort and makes the vehicle easier to control. At this time, the hydraulic power steering system has a complex structure and high cost, but it gradually replaced the manual steering system and became a standard configuration.

2. Introduction of rack steering system

One of the core components of the hydraulic power steering system is the steering rack. The traditional mechanical steering system uses gears and drive shafts to transmit the driver's turning force to the steering gear through the drive shaft to control the direction of the wheel. However, the introduction of the hydraulic power steering system changed the way this force is transmitted, and the rack became a vital component in the system.

The hydraulic power steering rack (Hydraulic Power Steering Rack) reduces the force required by the driver to turn the steering wheel through the hydraulic power steering system, making the steering process smoother and easier. At the same time, the rack design has greater advantages than the traditional steering system, with higher durability and lower failure rate. With the widespread application of hydraulic power steering technology, the rack has gradually become an indispensable core component in modern power steering systems.

3. The rise of electric power steering and the popularization of rack systems

After entering the 21st century, with the rapid development of electric power steering (EPS) technology, the power steering system has undergone changes again. The electric power steering system no longer relies on hydraulic oil, but directly provides power to the steering wheel through an electric motor, making steering more precise and efficient. The electric power steering system greatly reduces power loss and maintenance costs, but it also requires higher precision for the steering rack.

In the electric power steering system, the rack still plays an important role. Since the power provided by the electric power steering system is relatively stable, the precise design and material selection of the rack are crucial to the stability and service life of the system. With the continuous advancement of technology, the manufacturing precision and material quality of the power steering rack have been greatly improved, enabling it to adapt to more diverse needs.

Key factors for the popularity of power steering rack

1. The automotive industry's demand for comfort and safety

The popularity of power steering rack is closely related to the automotive industry's requirements for comfort and safety. With the continuous development of the automotive industry, especially in recent years, the superiority of the power steering system has become more and more obvious. Compared with manual steering, the hydraulic power steering rack provides lower steering force and higher handling stability, helping to reduce the driver's fatigue during long-term driving. The electric power steering system can provide smooth power while improving the accuracy of control.

In addition, the power steering rack can effectively reduce the wear and damage caused by excessive torque to other parts of the steering system (such as steering column, ball head, etc.), and enhance the safety of the vehicle. All these have made the power steering rack gradually become a mainstream technology and widely used in various types of cars.

2. Advances in manufacturing technology and cost reduction

The popularity of the power steering rack system is inseparable from the advancement of manufacturing technology. From early mechanical processing to current precision processing technology, the manufacturing cost and production difficulty of the rack have gradually decreased. The introduction of precision CNC technology, automated production lines and high-performance materials has greatly reduced the production cost of the power steering rack. As technology continues to mature, more automakers are able to integrate the power steering rack system into more types of vehicles, thereby achieving popularization.

3. Promotion of policies and environmental protection requirements

With increasingly stringent environmental regulations, automakers are under pressure to reduce fuel consumption and emissions. Although the hydraulic power steering system has advantages in comfort and performance, the use of hydraulic oil not only increases the energy consumption of the vehicle, but also has a certain impact on the environment. Therefore, the electric power steering system has gradually become the mainstream technology to replace the hydraulic power steering system. Although the electric power steering system no longer relies on hydraulic oil, the rack is still an indispensable and important part of the system, especially in providing accurate feedback and high stability. Therefore, the application range of the rack has been expanded.

Popularity of power steering rack in modern cars

At present, almost all modern cars, especially mid-to-high-end sedans and SUVs, are equipped with power steering rack systems. With the further popularization of electric power steering technology, the design and manufacturing technology of racks are also constantly developing. Modern power steering racks not only need to meet higher precision requirements, but also be able to withstand higher loads and stresses to ensure reliability and stability under complex driving conditions.

Some high-end models are even equipped with power steering systems with adaptive power assistance. This system uses sensors and electronic control units (ECUs) to adjust the power assistance of the steering rack in real time to adapt to different driving environments and speeds. The application of this technology makes the power steering system more intelligent and efficient, and further promotes the popularity of power steering racks.

Best Prices for High-Quality Steering Systems

Guangdong Diamond Auto Parts Co., Ltd. (DKM) is committed to providing affordable, high-quality power steering systems for automotive manufacturers and dealers worldwide. With a focus on producing steering systems for brands such as Toyota, Honda, and Mitsubishi, our products meet the highest industry standards. As a trusted supplier with over 20 years of experience, DKM offers cost-effective solutions that include low prices, promotions, and customized products for bulk purchasing.