What is a steering rack bushing?

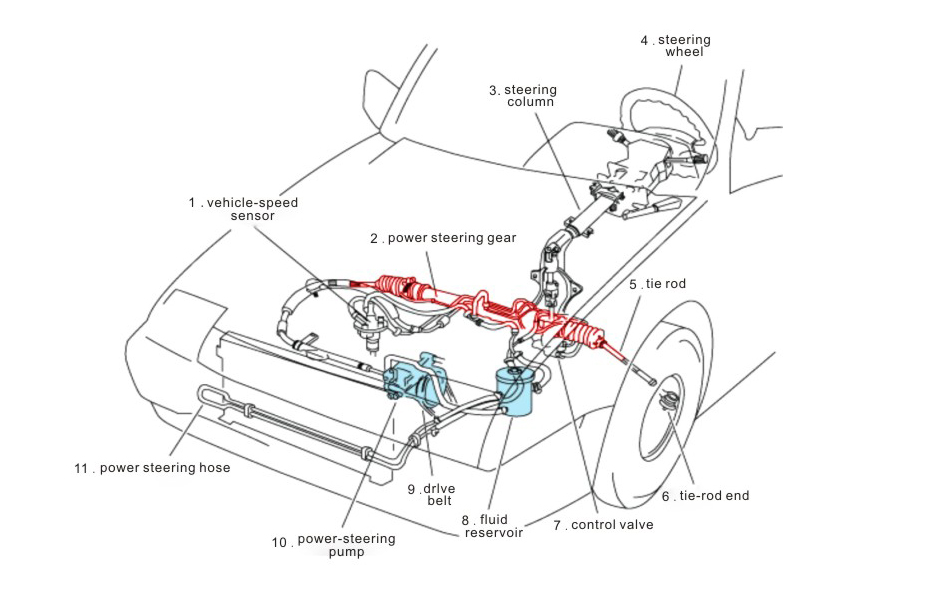

The steering system is an integral part of modern cars. It is responsible for effectively transmitting the driver's steering action to the wheels, enabling the vehicle to change direction. There are many key components in the steering system, among which the steering rack bushing, as a small but important component, plays a vital role in the entire steering system.

This article will introduce the definition, function, material, working principle and importance of the steering rack bushing to the steering system in detail. We will explore the role of the steering rack bushing in the car in depth and discuss its maintenance and replacement.

What is a steering rack bushing?

The steering rack bushing is a small friction bushing in the steering system. It is usually located between the steering rack and the steering gear, or where it is connected to the steering column. Its main function is to provide a smoother steering experience by reducing the friction between the rack and other steering components.

The steering rack bushing is essentially a bearing assembly that ensures the smooth operation of the steering system by providing support between the steering rack and the steering gear or other connecting parts. Since the steering system is subjected to pressure in different directions during the driving process of the car, the role of the bushing is to reduce friction, protect the steering rack and other components, and reduce unnecessary wear.

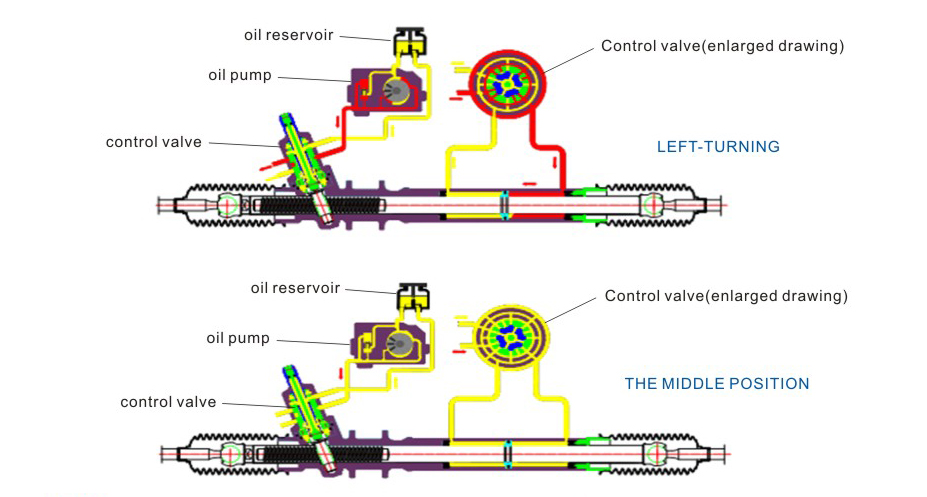

How does the steering rack bushing work?

The working principle of the steering rack bushing is similar to that of other types of bushings or bearings. It ensures the smooth operation of the steering system by providing a surface with less friction and reducing the friction between the rack and other components when working. The bushing is usually made of wear-resistant materials that can withstand the friction load under high pressure.

When the vehicle is driving, the steering rack meshes with the pinion to transmit the turning force on the steering wheel to the wheels. This process will generate a certain amount of friction and pressure. In order to ensure the smoothness of the steering system, the steering rack bushing provides additional support between the rack and its supporting components, helping the rack to slide or rotate smoothly, reducing friction, thereby avoiding unnecessary wear and noise caused by wear.

What are the materials of the steering rack bushing?

The steering rack bushing is usually made of wear-resistant, pressure-resistant, and low-friction materials, which can effectively reduce the heat and wear generated by friction during use. At present, common steering rack bushing materials include:

1. Metal bushing:

Metal bushings are usually made of metal materials such as aluminum, steel or copper alloy. Metal bushings have excellent load-bearing capacity and wear resistance, so they are suitable for steering systems that bear large loads. They can work at higher temperatures and pressures to ensure stability in long-term use.

2. Plastic bushing:

Plastic bushings are widely used in steering systems of light vehicles due to their low cost, light weight and low friction coefficient. Commonly used plastic materials include polytetrafluoroethylene (PTFE), polyurethane (PU) and nylon, which can effectively reduce friction and have good wear resistance.

3. Composite bushing:

In recent years, some high-end cars use bushings made of metal and plastic composites. These composites not only inherit the advantages of metal and plastic, but also improve the performance of the bushing through the structural design of the composite material. For example, the use of metal-based composite materials can improve the strength and durability of the bushing, while plastic-based composite materials can reduce friction and improve flexibility and responsiveness.

What is the role of steering rack bushings?

The steering rack bushing has the following main functions in the steering system:

1. Reduce friction:

The various components of the steering system will generate friction when working, especially the friction between the steering rack and other steering components. The steering rack bushing can reduce this friction, thereby ensuring the smooth operation of the steering system. Reducing friction can not only improve the flexibility of the steering system, but also reduce the heat and wear caused by friction, and extend the service life of the system.

2. Provide support:

The steering rack bushing also plays a supporting role. It can provide a stable support point for the steering rack to ensure the precise movement of the steering rack. The rack will bear the pressure from the steering machine when steering, and the bushing ensures the accuracy and stability of the rack movement through support and guidance.

3. Reduce noise:

Due to the existence of friction, the steering system may make unnecessary noise when working. The steering rack bushing reduces the friction between the rack and other components, reducing the noise generation and making the steering system quieter. Especially when driving at low speeds, the bushing can effectively reduce the noise caused by friction and improve the driving experience.

4. Reduce wear:

Long-term friction and pressure will cause wear of steering system components, which will affect steering performance. Steering rack bushings can effectively reduce the wear of key components such as racks and steering gears by reducing direct contact friction, and extend the service life of the steering system. Especially in high-load or harsh driving environments, steering rack bushings can play a protective role.

What are the common faults of steering rack bushings?

Although the steering rack bushing is a well-designed component, it still has some common faults with long-term use. The following are several possible faults of steering rack bushings:

1. Bushing wear:

The bushing will wear under long-term friction, especially when poor quality liquid lubricants or steering fluids are used, the wear resistance of the bushing will be reduced. Worn bushings can cause the steering system to become unstable and increase friction during steering.

2. Bushing aging:

The material of the bushing will age over time, especially plastic or rubber bushings. Aging bushings will lead to reduced steering system accuracy and may even cause bushing rupture, which will seriously affect the stability of steering.

3. Insufficient lubrication:

Lubrication is the key to ensure the proper function of the bushing. Insufficient lubrication will increase the friction between the bushing and the steering rack, which will increase wear and heat. If the steering system is not maintained for a long time, it may lead to insufficient lubrication problems, which will eventually affect the function of the bushing.

4. Loose or damaged bushing:

Loose or damaged bushing will directly affect the precise movement of the steering rack. Loose bushings may cause steering failure, inaccurate direction and other problems, affecting driving safety.

How to maintain and replace the steering rack bushing?

In order to ensure the long-term stable operation of the steering system, it is very important to regularly maintain the steering rack bushing. Here are some common maintenance and replacement suggestions:

1. Regular inspection:

Regularly inspect the various components of the steering system, including the steering rack bushing. Check whether the bushing has problems such as wear, aging, cracks, etc., and timely discover potential fault hazards. By checking the condition of the bushing, you can prevent the occurrence of faults in advance.

2. Lubrication and cleaning:

Clean the steering system regularly and provide proper lubrication for the rack and bushing. Using high-quality lubricants or lubricants can effectively reduce friction and extend the service life of the bushings. Ensure that the quality of the lubricant is good and avoid using lubricants that have deteriorated or contaminated.

3. Replace damaged bushings in time:

When the bushing is found to be worn or aged, it should be replaced in time. Replacing the steering rack bushing usually requires disassembly of some steering system components, so it is best to have a professional technician perform the operation.

4. Avoid overload operation:

Avoid overloading the steering system for a long time, especially under extreme driving conditions. Excessive use of the steering system will accelerate the wear and aging of the bushing and reduce its service life.

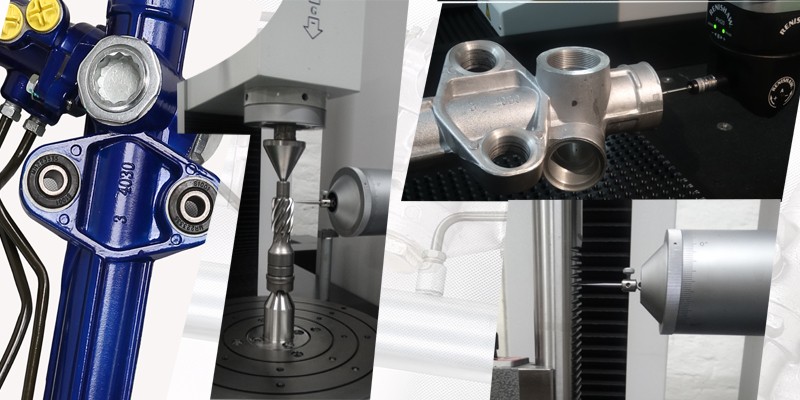

How do you ensure product quality and consistency?

Quality is at the core of DKM’s operations. We utilize over 280 sets of CNC and heat-treatment equipment and advanced automated lines to maintain tight tolerances and durable performance. We adhere to strict quality control systems and can provide clients with manufacturer-supplied certificates, test reports, and third-party inspection options.

Our high‐quality steering racks come at low manufacturer prices and are sold through wholesale channels with attractive promotions and reliable purchasing terms.