Is the power steering gear connected to the rack and pinion?

The power steering system is an integral part of modern cars, which makes driving easier by reducing the amount of effort the driver has to put into operating the steering wheel. The power steering gear, rack and pinion are the core components of the power steering system, where the power steering gear is the device that provides power assistance, while the rack and pinion is the direct component that transmits the force of the driver turning the steering wheel to the wheels.

So, is the power steering gear connected to the rack and pinion? In order to answer this question in detail, we need to have a deep understanding of the working principle of the power steering gear, the function of the rack and pinion, and the relationship between the two.

What is the role of the power steering gear?

The power steering gear is a mechanical device whose main function is to reduce the amount of effort required by the driver to turn the steering wheel. The power steering gear provides power assistance to the steering system using a hydraulic or electric drive system, thereby improving the comfort and flexibility of steering. In early cars, the steering system relied entirely on mechanical force, which meant that the driver needed to use a lot of force to turn the steering wheel, especially at low speeds or when parking.

With the advancement of technology, hydraulic power steering (HPS) and electronic power steering (EPS) systems were introduced into cars. The power steering gear not only reduces the driver's operating burden, but also improves the steering accuracy and responsiveness. In a hydraulic power steering system, the power steering gear usually includes a hydraulic pump and a hydraulic booster; in an electronic power steering system, an electric motor is relied on to provide power.

What is the role and principle of rack and pinion?

Rack and pinion constitute one of the most common steering mechanisms in modern cars, namely the rack and pinion steering system. This system is widely used in passenger cars and light commercial vehicles for its simplicity, directness, and fast response.

1. Rack:

The rack is a long strip-shaped component with teeth, and its length usually matches the width of the steering gear. The teeth of the rack mesh with the teeth of the pinion, and through this meshing method, the rack slides along the horizontal axis during steering. When the driver turns the steering wheel, the steering column drives the pinion to rotate, and the teeth of the pinion mesh with the rack, which in turn drives the rack to move left or right, thereby turning the wheel.

2. Pinion:

The pinion is a key component in the rack and pinion system. It is usually mounted at the end of the steering column and connected to the steering wheel through a bearing. When the driver turns the steering wheel, the steering wheel transmits force to the pinion through the steering column. The rotation of the pinion generates linear motion by meshing the tooth surface of the rack, thereby pushing the rack. This linear motion is converted into the steering action of the wheel.

What is the relationship between power steering gear and rack and pinion?

In order to answer the question of whether power steering gear is connected to rack and pinion, we need to understand the collaborative working relationship between power steering gear and rack and pinion. In traditional hydraulic power steering systems (HPS), power steering gear works closely with rack and pinion system to complete the steering task.

1. Relationship in hydraulic power steering system (HPS):

In hydraulic power steering system, power steering gear provides power assistance to the steering system through hydraulic pump. The hydraulic pump uses the power of the engine to transfer pressure to the power steering gear through hydraulic oil. When the driver turns the steering wheel, the steering wheel drives the pinion to rotate, which in turn drives the rack to move left and right. At this time, the hydraulic power steering gear provides additional assistance, making the rotation between rack and pinion easier.

The working principle of the hydraulic system is that when the steering wheel is turned, the hydraulic pump of the power steering gear applies pressure to the rack and pinion system to help push the rack, thereby reducing the steering burden of the driver when driving at low speeds and parking. The hydraulic system achieves steering assistance at different speeds by adjusting the oil pressure, usually providing greater assistance at low speeds and less assistance at high speeds to improve driving stability.

2. Relationship in the electronic power steering system (EPS):

In the electronic power steering system (EPS), the power steering gear no longer relies on the hydraulic pump, but is powered by an electric motor. The electric motor in the EPS system is usually installed near the steering column or the rack and pinion system, providing assistance to the pinion directly or through a transmission. Although the EPS system is different from the traditional hydraulic system in terms of power source, its working principle is similar to that of the hydraulic system, both of which reduce the driver's operating burden by changing the power provided to the rack and pinion system.

Compared with the hydraulic power steering system, the advantage of the EPS system is that it can automatically adjust the steering assistance according to the driving conditions, providing greater assistance at low speeds and reducing assistance at high speeds, thereby improving driving comfort and stability. Because it uses electric motors and electronic control, the EPS system has more precise control capabilities and also helps reduce the weight and energy consumption of the system.

3. The synergy of power steering gear, rack and pinion:

The power steering gear and rack and pinion are the two core components of the steering system. They are not directly "connected" to each other in terms of physical structure, but work together through control force and power assistance. With the help of hydraulic and electric power assistance, the driver can easily control the rotation of the steering wheel, and the rack and pinion in the steering system is responsible for converting the rotational motion into the steering action of the wheel.

Although the power steering gear is not directly connected to the rack and pinion, its working effect directly affects the operating efficiency of the rack and pinion. Without the power steering gear, the driver needs more force to turn the steering wheel, which will increase the load on the rack and pinion system, thereby affecting the steering accuracy and sensitivity.

Maintenance and maintenance of power steering gear, rack and pinion

Due to the important role of power steering gear, rack and pinion in the steering system, regular inspection and maintenance of these components are necessary measures to ensure the normal operation of the vehicle steering system. Here are some common maintenance and care recommendations:

1. Check the hydraulic oil of the power steering gear:

For hydraulic power steering systems, the quality and level of the hydraulic oil need to be checked regularly. If the hydraulic oil deteriorates or the level is too low, the power steering gear will not be able to assist, affecting steering performance. The cleanliness of the hydraulic oil is also critical, and contaminated hydraulic oil may cause wear of the power steering gear and its related components.

2. Check the wear of the rack and pinion:

Wear of the rack and pinion will affect the steering accuracy and comfort. Regularly check the tooth surfaces of the rack and pinion to ensure that they are not excessively worn or damaged. If excessive wear is found, the relevant parts should be replaced in time.

3. Check the electronic control unit (ECU) of the electronic steering system:

For the electronic power steering system (EPS), the function of the electronic control unit (ECU) is critical. Regularly check the working status of the ECU to ensure that the control of the electric motor is normal and avoid loss of steering assistance due to electronic control failure.

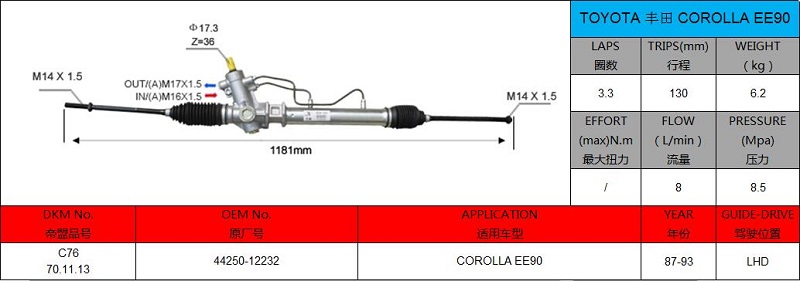

As a leading manufacturer of power steering systems, Guangdong Diamond Auto Parts Co., Ltd. (DKM) offers a wide selection of high-quality steering racks and gears for cars and commercial vehicles. Serving regions including Europe, Africa, Southeast Asia, and the Middle East, we provide competitive prices and promotions to help you save on large orders.

Purchasing from us ensures you receive reliable products at a low price, backed by a strong warranty and quality assurance!