Is it necessary to "break-in" after installing a new Ford hydraulic power steering rack?

For well-known car brands such as Ford, the hydraulic power steering rack is an important part of ensuring that the driver can easily control the vehicle. Whether it is daily driving or emergency steering, the hydraulic power steering system plays a vital role. As the vehicle ages, the steering rack may need to be replaced due to wear or failure. So, after installing a new hydraulic power steering rack, is it necessary to "break-in"?

This article will explore this issue in detail, analyzing the working principle of the hydraulic power steering system, the installation process of the new rack, and whether "breaking-in" is necessary.

How does the hydraulic power steering rack work?

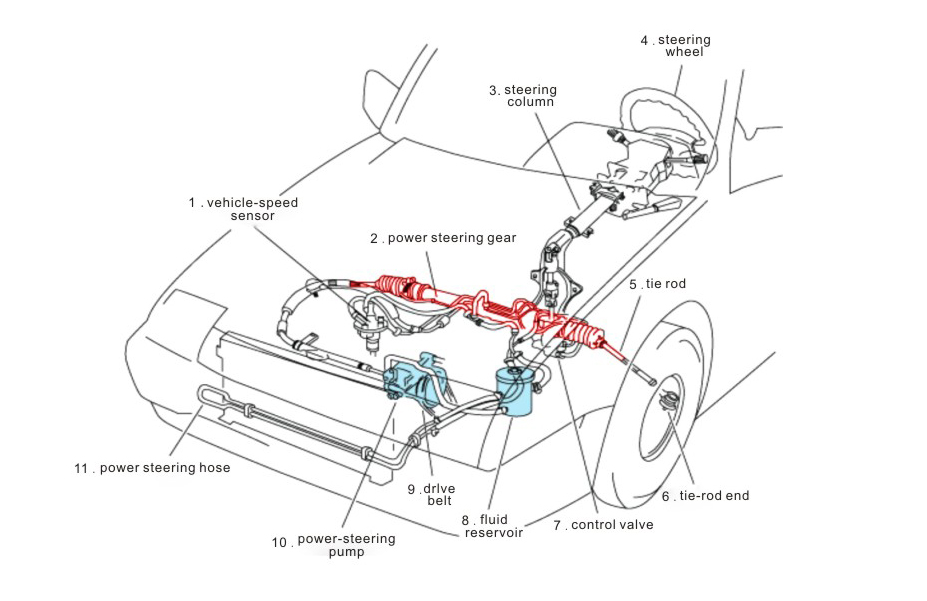

The hydraulic power steering system is widely used in the automotive industry. It helps the driver to control the steering wheel more easily through the power provided by the hydraulic pump. Specifically, the hydraulic power steering rack consists of a hydraulic system and a mechanical rack. The hydraulic system provides power to the steering system, and the mechanical rack converts the rotation of the steering wheel into the steering action of the wheel by meshing with the pinion.

In the hydraulic power steering system, the hydraulic pump converts power into hydraulic energy through the drive of the power steering pump, and transmits the hydraulic oil to the steering rack through the pressure pipe. When the driver turns the steering wheel, the steering rack helps adjust the direction of the wheel through the pressure of the hydraulic oil, thereby reducing the driver's steering burden.

The design of the hydraulic power steering rack needs to take into account multiple factors, including bearing large mechanical loads, wear resistance, corrosion resistance, etc. Over time, the rack will be affected by friction, pressure changes and hydraulic oil, and may be damaged, leaked or worn, so replacing the steering rack has become a common item in vehicle maintenance.

What is the process of replacing the hydraulic power steering rack?

When replacing the Ford hydraulic power steering rack, the maintenance technician will follow a series of steps. The specific process is as follows:

· Inspection and evaluation: First, the maintenance personnel need to conduct a comprehensive inspection of the existing steering system to confirm whether the steering rack is faulty. Usually, the problem of the steering system can be identified by checking for leakage of hydraulic oil, noise when steering or heaviness of operation.

·Remove the old rack: Once it is confirmed that the steering rack needs to be replaced, the maintenance personnel will remove the old rack. This process includes disconnecting the hydraulic lines of the steering system and removing the brackets that fix the steering rack.

·Install the new rack: After removing the old rack, the maintenance personnel will install the new hydraulic power steering rack in place. During the installation process, it is necessary to ensure that the connection between the new rack and other steering system components (such as steering wheels, wheels, etc.) is firm.

·Connect the hydraulic lines and check: After the installation is completed, the maintenance personnel will reconnect the hydraulic lines and check whether the hydraulic oil is sufficient. At the same time, it is necessary to check the meshing state of the new rack to ensure that there is no jamming.

·Test run and adjustment: After the installation is completed, the technician will test the working state of the hydraulic power steering rack. If the steering system is operating normally, make final adjustments to the system after the test run.

The "running-in" problem of hydraulic power steering rack

The concept of "running-in" originated from the field of automobile engines. It refers to the process in which new components (such as engines, gears, etc.) adapt and gradually optimize their matching degree through specific methods and lower loads during initial operation, thereby extending the service life of the components. For some mechanical components, especially highly precise mechanical devices, the running-in process helps to adjust the matching degree between various components, reduce friction, and prevent excessive wear.

So, after installing a new hydraulic power steering rack, is a similar "running-in" process also required?

· Initial operation of the hydraulic system: The main working principle of the hydraulic power steering system is to help the driver turn the steering wheel through the pressure of the hydraulic oil. After installing a new steering rack, the hydraulic system needs a certain amount of time to exhaust and optimize the flow of hydraulic oil. Some unstable situations may occur during this process, such as the steering wheel turning slightly heavy or not smooth, which is usually caused by the hydraulic oil not fully filling the system or the bubbles not being discharged. This situation generally disappears naturally in a short time and does not require special "running-in" operations.

·Necessity of running-in: Unlike engines or gearboxes, hydraulic power steering racks do not need to be run-in by running at low speed for a long time. The meshing surface between the steering rack and the pinion is usually precisely processed during the production process, and the degree of fit is high. In other words, the "running-in" of the rack is more achieved through the normal circulation of hydraulic oil and operation during actual driving.

In fact, the "running-in" period of the hydraulic power steering system is relatively short. Usually after the first test run, the hydraulic system will automatically adjust to ensure that the steering system can run smoothly. If there are problems such as continuous abnormal noise or inflexible operation, it may be caused by other factors (such as insufficient hydraulic oil, pipeline leakage, etc.), not "running-in" problems.

·Importance of hydraulic oil: In the early stage of use of a newly installed power steering rack, if the hydraulic oil is insufficient or of poor quality, it may cause abnormal performance of the steering system. Hydraulic oil not only plays the role of lubrication and sealing, but also directly affects the working efficiency of the steering system. After installing a new rack, it is crucial to ensure the quality and sufficient level of hydraulic oil.

Operation suggestions: Although the newly installed steering rack does not require a long "running-in", in order to ensure the smooth operation of the steering system in the initial stage, it is recommended that the driver:

· Carry out a short test drive at low speed to observe whether the steering wheel operation is smooth.

· Check the hydraulic oil level regularly to ensure that the oil is sufficient.

· Avoid excessive steering or high-speed driving in the initial stage to avoid unnecessary load on the new rack and hydraulic system.

Through these simple operations, it can effectively ensure that the steering system returns to the best working condition as soon as possible.

Affordable Power Steering Gears for Wholesale Buyers

Guangdong Diamond Auto Parts Co., Ltd. (DKM) is a trusted supplier of power steering gears, specializing in high-quality automotive parts at affordable prices. We have over two decades of experience producing steering systems for major vehicle brands, including Toyota, Honda, and Mitsubishi. Our factory in Foshan is equipped with advanced technology to ensure the highest standards of production.

If you are interested in purchasing steering gears at low prices, we provide promotions, quotes, and discounts for bulk purchases. Get in touch for more information!