Can rack and pinion steering be used in quad bikes?

A quad bike (ATV, All-Terrain Vehicle) is a versatile all-terrain four-wheeled vehicle, commonly used in off-road, agriculture, leisure and entertainment and other fields. The steering system of a quad bike, as one of its core drivers, is related to the vehicle's handling, stability and safety. Traditional quad bikes use a flexible steering system, which is usually composed of a rocker arm, a steering column, a ball head and a tow bar, and relies on mechanical means to convert the rotation of the steering wheel into the rotation of the wheel.

However, with the advancement of technology, more and more quad bike manufacturers are beginning to consider using different types of steering mechanisms to improve handling and driving experience. As a common steering solution in traditional cars and trucks, whether the rack and pinion steering system can be used in quad bikes has become a question worth exploring.

This article will comprehensively analyze whether the rack and pinion steering system is suitable for quad bikes from the aspects of the basic principles of the steering system, the working characteristics of the rack and pinion, the structural requirements of quad bikes and possible challenges, and explore its feasibility and potential advantages.

What is the working principle of the steering system?

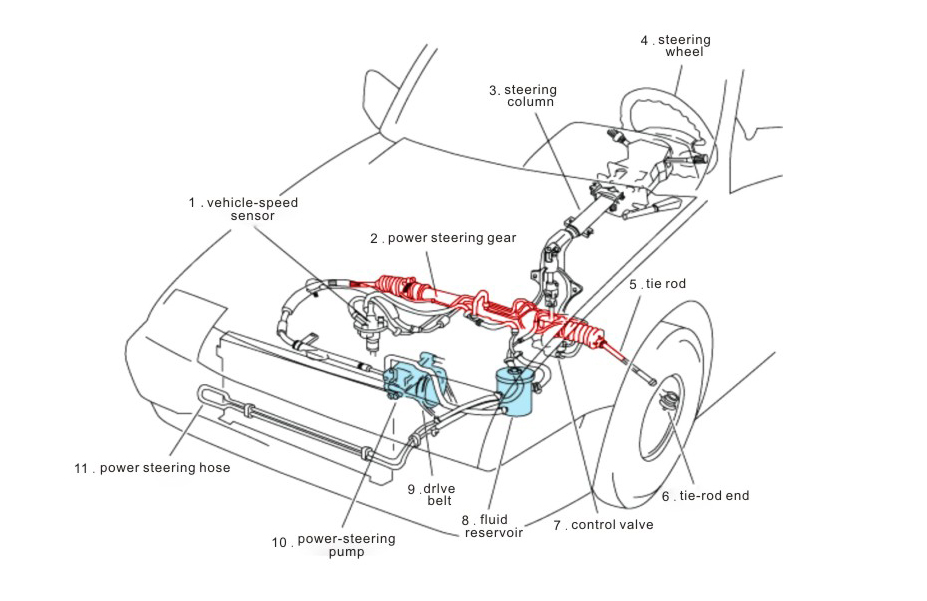

Whether it is a four-wheeled motorcycle, a car or a truck, the basic task of the steering system is to convert the driver's rotation input of the steering wheel into the rotation output of the wheel. The steering system is usually composed of a steering wheel, a steering column, a steering gear, a ball head, a tow bar, etc. On traditional four-wheeled motorcycles, the design of the steering system is mainly mechanical and manual. Its core components are usually connected to the wheels through rocker arms, and the wheels are controlled through connecting components such as tie rods.

● Steering wheel input: The driver applies steering force by turning the steering wheel.

● Steering column and steering gear: The rotation of the steering wheel is transmitted to the steering gear through the steering column. The steering gear transmits the force to the wheel through different mechanisms according to the input rotational force.

● Tie rod and ball head: The tie rod and ball head system realizes the force transmission between the wheel and the steering gear, usually converting the rotation of the steering gear into the rotation of the wheel in a "crank" manner.

How does the rack and pinion steering system work?

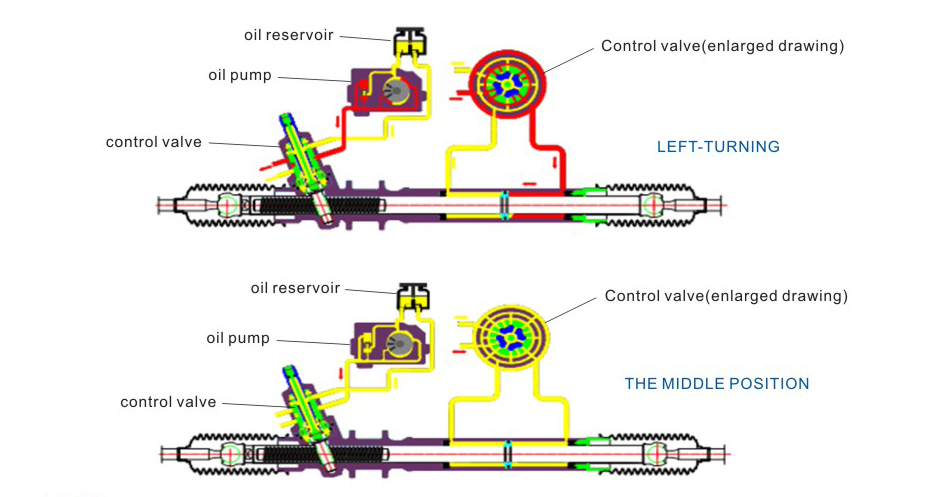

The rack and pinion steering system is a common mechanical transmission method, and its working principle is mainly based on the method of gear meshing. A rack is a long gear whose teeth mesh with a pinion. The rotation of the gear drives the rack to move linearly, ultimately achieving steering movement. Rack and pinion steering systems are widely used in vehicles such as cars and trucks, and can effectively improve the accuracy and stability of steering.

● Rack: A rack is a linear component with a tooth shape, usually matched with a pinion. Racks are usually used in steering systems, which convert the rotation of the pinion into linear displacement to drive the rotation of the wheels.

● Pinion: The pinion is installed on the main shaft of the steering gear. By meshing with the rack, the rotational force input by the driver is converted into linear movement, ultimately achieving the steering action of the vehicle.

● Advantages: Rack and pinion steering systems usually have high accuracy and responsiveness, compact structure, high force transmission efficiency, and can provide a smoother steering experience.

What are the steering requirements of quad bikes?

A quad bike (ATV) is a vehicle with strong off-road capabilities and good maneuverability, usually used in complex terrain environments. Compared with traditional cars or trucks, the structure and use of four-wheeled motorcycles have their own unique requirements, which poses different challenges to the design of steering systems.

1. Adaptability of the steering system

A significant difference between the structure of four-wheeled motorcycles and traditional cars is the design of their frames and suspension systems. The frames of four-wheeled motorcycles are usually simpler and lighter, and the wheels are more independent and flexible. When designing the steering system, the versatility of four-wheeled motorcycles, the ability to drive on complex roads, and the flexibility of the driver's operation must be taken into account. Therefore, the steering system needs to have:

● High responsiveness: Four-wheeled motorcycles often need to perform fast steering operations on uneven ground, so the response speed of the steering system is required to be high.

● Simple and durable: Four-wheeled motorcycles usually travel on complex road conditions, so their steering systems need to have high durability while ensuring accuracy.

● Light weight and small size: The design of four-wheeled motorcycles emphasizes lightness, so the size and weight of the steering system must be as small as possible.

2. Load and stability of the steering system

The steering system of a four-wheeled motorcycle bears a greater load than that of ordinary cars such as sedans, because four-wheeled motorcycles often travel on rugged terrain, requiring the steering system to have strong stability. In this case, the design of the steering system needs to be able to cope with requirements such as high load, low friction, and good mechanical distribution. The rack and pinion steering system has certain advantages in these aspects because it can achieve high accuracy and force transmission efficiency with a smaller volume and lighter weight.

Can rack and pinion steering be used in four-wheeled motorcycles?

Based on the unique needs of four-wheeled motorcycles, whether the rack and pinion steering system is suitable for application in its steering mechanism must be considered comprehensively. Below, we will analyze it in detail from several key factors.

1. System accuracy and controllability

The rack and pinion steering system can provide high accuracy and stable controllability due to its precise gear meshing design. For four-wheeled motorcycles, this high-precision steering system can ensure that the driver can still maintain a good control experience in off-road or complex road conditions. Especially in situations where high response speed and precise control are required, rack and pinion steering can reduce the reverse movement of the steering wheel and provide more sensitive feedback.

2. Load-bearing capacity and durability

The load-bearing capacity of rack and pinion steering mainly depends on the material, design and lubrication system of the gears. For a vehicle like a four-wheeled motorcycle that is subject to high loads and complex road conditions, the steering system needs to withstand the test of long-term heavy loads and harsh conditions. Rack and pinion steering systems, especially under high load conditions, are susceptible to friction, corrosion and wear. If they are not effectively maintained and lubricated, such systems may have problems with poor durability. Therefore, when using rack and pinion steering systems, special attention should be paid to the selection of materials and the improvement of durability.

3. Weight and volume

Four-wheeled motorcycles emphasize lightness and high maneuverability, while rack and pinion steering systems may increase the overall volume and weight of the system due to their more complex structure. This may not be applicable to some high-performance four-wheeled motorcycles, because the increase in weight and volume will affect the vehicle's handling, fuel efficiency and sports performance.

4. Cost and Manufacturing Process

Compared with traditional rocker arm steering systems, rack and pinion steering systems usually increase manufacturing costs. Manufacturing precision racks and pinions requires high-precision processing equipment and processes, which may lead to an increase in overall production costs. In addition, the repair and replacement costs of rack and pinion steering systems are relatively high. For some low-cost, low-end models of four-wheel motorcycles, the use of rack and pinion steering systems may make them uncompetitive in the market.

Reliable Supplier of Rack and Pinion Steering

Founded in 1996, Guangdong Diamond Auto Parts Co., Ltd. (DKM) has established itself as a leading manufacturer of power steering gears. Our products are designed to meet the rigorous demands of the automotive industry and are sold to OEMs and dealers in regions such as the US, Europe, and Southeast Asia. We offer affordable pricing and high-quality steering systems for a wide range of vehicle brands, including Toyota, Honda, and Volkswagen. Contact us today for wholesale rates, promotions, and quotes!