Can a rack and pinion steering system use a tilt mechanism?

In the automotive industry, rack and pinion steering systems are widely used in various types of vehicles. This system has been widely used in modern vehicles due to its simple structure, quick response and light weight.

At the same time, as vehicle design pays more and more attention to driver comfort and ease of operation, many cars are equipped with adjustable tilt steering wheels (tilt steering) or electric adjustment functions to improve driving comfort.

This raises an important question: Can a rack and pinion steering system be combined with a tilt mechanism? This article will explore this issue in depth and analyze the feasibility, technical challenges and application status of the combination of the two.

How does a rack and pinion steering system work?

The rack and pinion steering system is one of the most common steering methods currently available. It mainly consists of two core components: a rack and a pinion. The rack is a long metal strip with teeth, and the pinion is a disc with teeth. The steering wheel is connected to the pinion through the steering shaft. When the driver turns the steering wheel, the pinion drives the rack to move left and right through the gear meshing, thereby driving the wheels to turn. This system has become the mainstream design of automotive steering systems due to its simple and efficient structure and good handling performance.

The advantages of the rack and pinion steering system are its direct control feel and low mechanical loss. This system allows the driver to achieve precise steering operations with less force and reaction time. However, in some special cases, the driver may need to adjust the angle of the steering wheel for a more comfortable driving experience, and then a tilt mechanism is needed.

What is a tilt mechanism?

A tilt mechanism is a device that allows the steering wheel to be adjusted up and down within a certain range. The driver can adjust the position of the steering wheel manually or electrically to suit personal driving needs and comfort. The design of the tilt steering wheel can help the driver adjust the distance between the seat and the steering wheel, improve the driving posture, and thus reduce fatigue from long-term driving. Many high-end cars, SUVs and some mid-size cars are equipped with this function to enhance the driving experience.

The working principle of the tilt mechanism is relatively simple. In most cases, it is achieved by a hinge device and an adjustment rod to achieve the up and down movement of the steering wheel. The steering wheel support rod is equipped with a hinge structure. The driver releases the locking mechanism by pulling the adjustment lever, allowing the steering wheel to move freely within a tilt angle range. The electric adjustment version uses an electric motor to complete the tilt operation, further improving convenience.

Can a rack and pinion steering system use a tilt mechanism?

When we discuss the possibility of combining a rack and pinion steering system with a tilt mechanism, the core issue is whether the tilt adjustment of the steering wheel can be allowed without affecting the accuracy and stability of the steering system. The combination of these two systems involves multiple aspects of mechanical design, structural stability and safety.

• Structural compatibility: The rack and pinion steering system and the tilt mechanism are highly compatible in structure. The tilt mechanism mainly acts on the mounting part of the steering wheel, that is, the connection structure between the steering wheel shaft and the steering column. Adjusting the position of the steering wheel through the tilt mechanism does not affect the meshing between the rack and the pinion, because the main work of the steering system is to transmit power between the steering column and the steering gear. Therefore, in theory, the rack and pinion steering system and the tilt mechanism can coexist.

•Tilt mechanism design challenges: Although rack-and-pinion steering systems can be used together with tilt mechanisms in theory, in practice, there are still certain design challenges. The most important point is how to ensure that the steering system's accuracy and response speed are not affected when the steering wheel angle is adjusted. Since the adjustment of the steering wheel will change the angle and position of the steering column, the designer needs to use a precise mechanical structure to ensure that the steering wheel adjustment will not cause the meshing between the steering rack and the pinion to loosen or wear, thereby affecting the smoothness of the steering.

In addition, the tilt mechanism needs to ensure stable operation under various driving conditions, which requires its design to have sufficient durability and reliability. If the tilt mechanism is not designed properly, it may become loose, make abnormal noises, or even fail, which is very dangerous for the steering system. Therefore, the combination of the tilt mechanism and the steering system needs to make corresponding guarantees in terms of accuracy and stability.

•Challenges of the electric adjustment system: As a more efficient and convenient way to adjust the steering wheel, the electric adjustment system has gradually become a standard feature of many high-end vehicles. When combined with the rack-and-pinion steering system, the electric motor, sensor, and control unit of the electric adjustment system need to work in coordination with the electronic control part of the steering system. This requires the electronic system to have a high degree of integration and good fault tolerance to ensure that the steering system can still maintain precise operation and stable working state during the steering wheel adjustment process.

Since the electric adjustment system needs to consume a certain amount of electricity, it puts higher requirements on the design of the battery management system. Especially in electric vehicles (EVs), the battery capacity is limited. How to reasonably allocate power resources so that the electric power steering system and the electric tilt adjustment system can coexist and maintain efficient operation is a technical problem that needs to be solved.

Solutions in practical applications

In order to realize the combination of rack and pinion steering system and tilt mechanism in practical applications, automobile manufacturers usually take some technical means to ensure the coordination and safety of the two. The following are some common solutions:

• Strengthen the steering column design: In some high-end models, the steering column design usually uses reinforced materials and precision processing technology to ensure that the meshing between the rack and the pinion is still accurate when the steering wheel is tilted. By adding a reinforced support structure to the steering column, the distortion and looseness during steering wheel adjustment can be effectively avoided.

•Optimization of electronic control system: Many modern vehicles use electronic power steering (EPS) systems, and the electric version of the tilt mechanism is also connected to the EPS system through an electronic control unit (ECU). Through precise electronic control, the state of the steering system can be monitored and adjusted in real time to ensure that the steering wheel adjustment does not affect the steering accuracy.

•Proper design of tilt range: When designing a tilt mechanism, the tilt range is usually limited according to ergonomics and driving comfort requirements. With a reasonable tilt angle range, manufacturers can ensure that the adjustment of the steering wheel does not negatively affect the driver's driving posture and control, while ensuring the stability of the steering system.

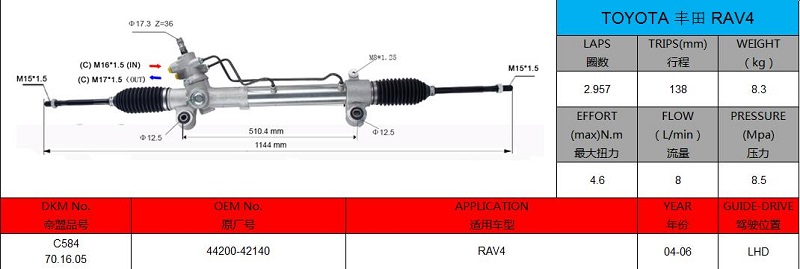

Steering Gear Solutions for Bulk Buyers

Guangdong Diamond Auto Parts Co., Ltd. (DKM) specializes in producing high-quality power steering gears for automotive manufacturers and dealers worldwide. Our products are designed for popular vehicle brands such as Toyota, Honda, and Mitsubishi. We offer affordable pricing, customized solutions, and timely delivery to suit your purchasing needs. With a focus on providing competitive prices and bulk purchasing options, DKM is your trusted supplier of steering gears!