How is the rack and pinion gear designed?

The design of rack and pinion gear is a crucial part of modern steering system engineering. As the core component of the vehicle steering system, the design of rack and pinion gear not only directly affects the driving experience, but also involves safety, durability and efficiency. This complex mechanical component needs to combine knowledge from multiple fields such as material science, mechanical principles and vehicle dynamics in the design process to ensure that it can meet the actual application needs. This article will discuss in detail the design principles, key technologies and specific applications of rack and pinion gear in vehicles.

What is the principle of rack and pinion gear?

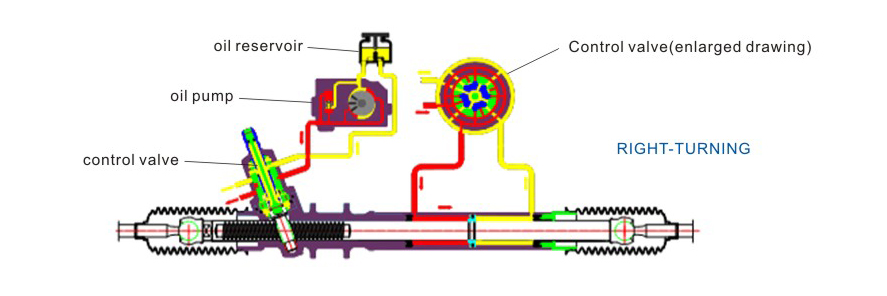

Rack and pinion gear is a common mechanical transmission device consisting of a pinion and a rack. The pinion is usually connected to the steering shaft, while the rack is a long metal rod with teeth on its surface along the length. After the two are meshed, the rotating gear converts the rotational motion into the linear motion of the rack. The core goal of this design is to achieve accurate transmission between the rotation of the steering wheel and the steering angle of the wheel.

In the automotive steering system, the rack and pinion gear structure has the following basic functions:

● Steering force transmission: The force of the steering wheel is transmitted to the steering link and the wheel through the rack and pinion gear system to achieve wheel steering.

● Deceleration and force increase: The rack and pinion gear system converts the small torque of the steering wheel into a larger steering force through the mechanical advantage of meshing transmission, reducing the driver's operating burden.

● Motion conversion: Convert the rotational motion of the steering wheel into the linear motion of the rack, thereby driving the wheel to turn left or right.

What are the key technologies in the design of rack and pinion gear?

The design of rack and pinion gear requires comprehensive consideration of multiple factors, including tooth shape design, material selection, manufacturing accuracy and lubrication system. The following are the key technologies in its design process.

1. Tooth shape design

The tooth shape is the core of the design of the rack and pinion gear system. The common tooth shape is the involute tooth shape, which has the following advantages:

● Smooth transmission: The involute tooth shape can ensure smooth transmission during the meshing process and reduce vibration and noise.

● Efficient transmission: Its design can minimize energy loss and improve transmission efficiency.

● Easy to manufacture: The processing method of involute tooth profile is mature and suitable for mass production.

In addition, to meet the needs of different models, designers may also adjust the gear tooth height, tooth width and tooth pitch to optimize system performance.

2. Gear ratio and steering ratio design

The gear ratio and steering ratio directly affect the vehicle's handling performance:

● Gear ratio: refers to the ratio of the number of teeth between the gear and the rack. A larger gear ratio can increase steering force but reduce steering speed.

● Steering ratio: refers to the ratio between the steering wheel rotation angle and the wheel steering angle. A well-designed steering ratio can find a balance between handling sensitivity and stability.

Generally speaking, the steering ratio of sports vehicles is smaller to improve sensitivity, while the steering ratio of large vehicles is larger to enhance stability.

3. Material selection

The rack and pinion gear system needs to withstand huge mechanical loads, so the choice of materials is crucial. Common materials include:

● Alloy steel: It has high strength, high hardness and good wear resistance, and is suitable for manufacturing gears.

● Carbon steel: has good processing performance and impact resistance, suitable for manufacturing racks.

● Coating technology: Applying chrome plating or nitriding treatment on the tooth surface can further improve wear resistance and corrosion resistance.

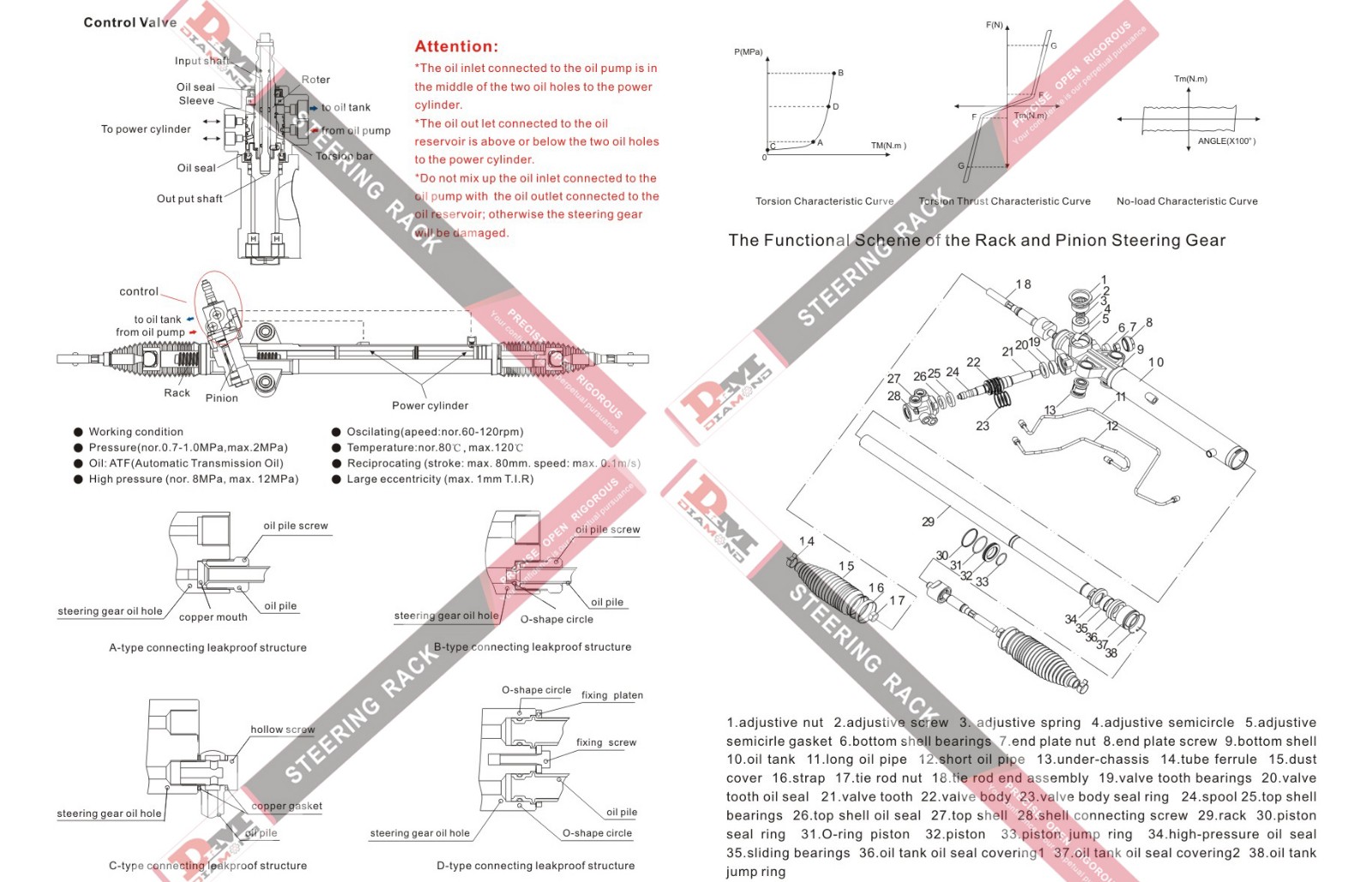

4. Tooth clearance control

Tooth clearance is the gap between the gear and the rack. Reasonable tooth clearance design can reduce noise and wear during meshing and avoid system jamming. Too large tooth clearance will cause slow system response, while too small tooth clearance may cause jamming or excessive wear.

5. Lubrication and sealing

Lubrication is an important guarantee for the normal operation of the rack and pinion gear system:

● Lubricating oil: Choosing the right lubricating oil can reduce friction and wear and extend service life.

● Seal design: In order to prevent dust, moisture and other impurities from entering the rack and pinion gear system, designers usually add rubber seals or protective sleeves.

What are the specific steps of rack and pinion gear design?

In the actual design process, the design of rack and pinion gear usually includes the following steps:

1. Demand analysis

Determine the design goals of rack and pinion gear according to the vehicle type, purpose and performance requirements. For example:

How much steering force is required?

What is the maximum steering angle of the wheel?

What is the expected service life and maintenance cycle?

2. Parameter calculation

The key parameters of rack and pinion gear, including pitch, tooth height, tooth width, number of teeth and meshing angle, are calculated by formula. Designers need to ensure that these parameters meet the standards and meet actual needs.

3. Material selection and verification

According to the calculation results and load requirements, select the appropriate material. Then verify whether the material performance meets the requirements through simulation experiments or actual tests.

4. Model design and optimization

Use computer-aided design (CAD) software to draw a three-dimensional model of rack and pinion gear. Use finite element analysis (FEA) to simulate its stress conditions under various working conditions and optimize the structural design.

5. Manufacturing and assembly

The manufacturing process includes forging, cutting and heat treatment. During assembly, the meshing accuracy of the rack and pinion gear needs to be ensured, and lubrication and sealing treatments need to be performed.

6. Testing and Verification

The reliability and performance of the design are verified through bench tests and road tests. If problems are found, the design needs to be improved and retested.

What are the challenges in rack and pinion gear design?

Although rack and pinion gear design is very mature, the following challenges are still faced during the design process:

1. Load variation

The load requirements of different models vary greatly. For example, heavy trucks need to withstand greater steering forces, while small cars require higher sensitivity.

2. Vibration and noise control

Rack and pinion gears may generate vibration and noise during operation, which has a negative impact on the driving experience. Designers need to mitigate this problem by optimizing the tooth shape and lubrication system.

3. Space constraints

The engine compartment and chassis space of the vehicle are limited, so the design of the rack and pinion gear needs to be as compact as possible to fit into the small installation space.

4. Cost control

High-performance materials and complex manufacturing processes increase costs, so designers need to find a balance between performance and cost.

What are the applications of rack and pinion gear in automobiles?

Rack and pinion gear is widely used in various types of vehicles, including:

● Sedans: mainly compact rack and pinion gear, pursuing smooth handling performance.

● SUVs: need to take into account both urban driving and off-road performance, rack and pinion gear design is more durable.

● Racing cars: emphasize sensitivity and response speed, rack and pinion gear design pursues extreme performance.

DKM: Affordable Steering Gear for Global Markets

Since 1996, Guangdong Diamond Auto Parts Co., Ltd. (DKM) has been supplying high-quality power steering gears for major automotive brands worldwide. Our products, including steering systems for Toyota, Honda, Mitsubishi, and more, are manufactured with precision and care to ensure optimal performance. With our production capabilities, we can offer bulk purchasing options at competitive prices. If you're looking to buy steering gears at wholesale prices, DKM provides affordable, high-quality products and exceptional service!